How To Use Fusion 360

And we’re all set. We have just upgraded the firmware to the GoPro Fusion. Stay tuned in to 360VRVoice for more videos, tutorials and more about the GoPro Fusion. And please join GoPro Fusion Studio Users. And give a facebook LIKE for 360VRVOICE. Thanks for watching. Designing Mechanisms using Fusion 360 4.6 (35 ratings) Course Ratings are calculated from individual students’ ratings and a variety of other signals, like age of rating and reliability, to ensure that they reflect course quality fairly and accurately.

I currently use Fusion 360 alongside with a couple of other applications, depending on the specifics of the project. Sometimes it's easier to model objects in. Fusion 360 Bodies and Components in Summary So, essentially Bodies form the geometric representation of your designs, either independently or as a result of relationships with other Bodies.Then Components allow you to define an assembly structure, and via the use of Joints, you can determine how parts and sub-assemblies function with respect to.

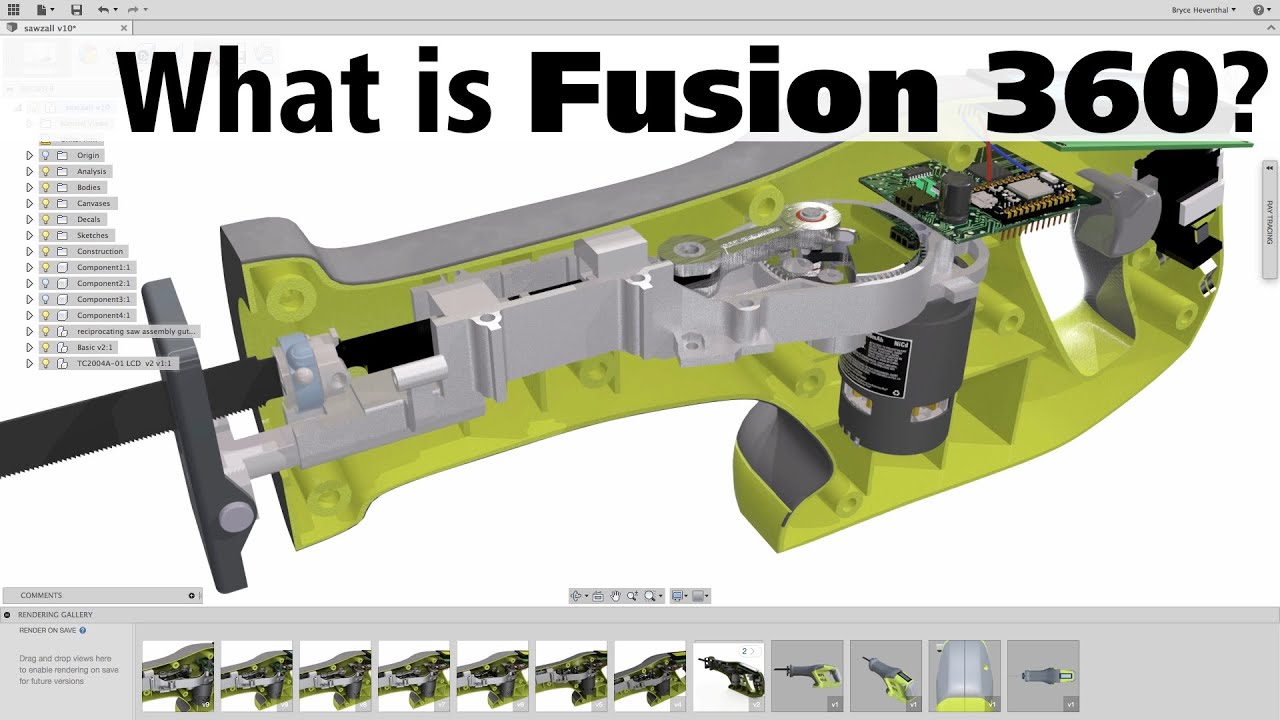

> > > Fusion 360 3D Tutorial: Prepare your model for 3D Printing with Fusion 360 This tutorial is designed for users of Fusion 360 who are interested in 3D printing and wish to know the optimal way to successfully create a printable model using this software. The tutorial will provide users with practical guidelines for modeling, optimizing and exporting an object for 3D printing. At the end of this 3D printing tutorial, you will know: • Modeling for 3D printing with Fusion 360 • Analyzing and exporting your 3D file optimally for 3D printing • Correct any modeling problems Then, you will be able to upload your 3D models on our website and 3D print them! Is a simple and powerful ergonomic Computer Aided Design (CAD) software developed by, often used for 3D printing projects.

Initially conceived for small and medium enterprises (SME) and designers, this 3D modeling software is increasingly being used by a diverse population of people in the home and office setting. This 3D CAD software provides a number of modules that are effective for a large range of applications including sketching, sculpting, and the ability to generate complex curved services, which can subsequently be turned into three-dimensional outputs and 3D printed products. This 3D design software is also affordable with Consistent with his pre-existing Cloud strategy, Autodesk has developed Fusion 360 to be accessible for collaborative design to promote innovation and synergetic activities between teams of a design agency or an SME. Its user interface is easy to get started with and will make it simple for any CAD designer to create its STL files, ready for 3D printers, and give birth to great 3D printing projects. This 3D design tool can be downloaded from the.

There are several options, from a free 1-year trial version to the ultimate version of this 3D design tool. There is a dynamic 3D CAD designer community that is working with Autodesk Fusion 360. Although this 3D design software is not open source, Autodesk allows users to develop ( add-in) applications and make them available on their platform. This allows each user to customize their 3D CAD software to best suit their needs. In this 3D printing tutorial, we will introduce you to the 3D features of Autodesk Fusion 360.

Fusion 360 Download Free

We will also give you special tips to create the best 3D printed products, and to optimize your files for the additive manufacturing technology. After this introduction to Fusion 360, you should be ready to send us your 3D model.

Just make your choice between our, and place your order! Do you need a bit more help before getting started with additive manufacturing? You will find many video tutorials on YouTube to help you create great 3D models!

How To Use Fusion 360 Sheet Metal

In the video above we look at the Sketch Basics of constraints and dimensions for Fusion 360. In this example, we are going to sketch up a basic shape, while following a few sketch rules. It’s worthwhile to turn on the origin, as it is important we connect our first sketch entity to it. Remember, you can only sketch on a face or a plane. Since we don’t have any solids on the screen, when starting with an empty canvas, we will be picking a plane for our first sketch. When you start your sketch, just create something close enough to your finished geometry. You will use constraints and dimensions to tie everything down afterward.

How To Use Fusion 360 For Aircraft Design

It is a good rule to start adding constraints before dimensions. Constraints are like rules for the sketches. For this example, we will apply horizontals and perpendicular constraints. When you are applying your constraints and dimensions, your final goal is to fully define the sketch. This means that the sketch is completely fixed.